|

|

Fuzhou AOMAG Magnetics CO.,Ltd was established in 1996 and specialized in R&D, production and sales of NdFeB magnets and magnetic assemblies.As a magnetic materials application technology expert, the company owns advanced magnet material properties analysis facilities and testing instruments, professional analysis software and experienced senior technical engineers to help customers better select the appropriate magnetic materials.

Our main product is NdFeB magnet and Frrite magnet, NdFeb magnet is widely used in motors,wind power generators,Oil power,Car industrial,Electronic industrial,IT,Sports equipment,armarium,speaker,and civilian industrial like Toys,gift,printing,box, etc.

Challenge to excellence and pursuing perfection is the management idea of our company, offering the reliable products is the operation aim of our company, satisfying customers with good products and service is the purpose that our company seeks for and the sustained improvement in quality is the way that our company develops. And work together with all staffs to create a more competitive and cohesive advanced enterprise.

We highly appreciate all people from different circles who have been supporting and helping our company's development. As always, we warmly welcome new and old customers to work with us together to create a prosperous future.

|

|

|

|

|

|

| Sm2Co17 |

Feature of Sintered SmCo:

The best temperature characteristics in the rare-earth magnet family

Manufactured by powder metallurgical process involving the sintering of powder under vacuum.

Both grades of SmCo5 and Sm2Co17, commonly referred to as 1:5 and 2:17 material are available.

Good corrosion resistance and no special surface treatment required excellent for compact designs

where high working temperature is a major concern.

Grinding and slicing operations possible

Application:

applied to various electric motors, instruments, sensors, detectors, radar, and other high-tech equip-

ment.

Magnetic property parameters of Sintered Sm2co17

材料牌号 |

剩磁 Br

|

磁感应矫顽力(最小值)HcB |

内禀矫顽力(最小值)HcJ |

最大磁能积

(BH)max |

居里温度 Tc |

工作温度

Tw |

剩磁温度系数 α(Br) |

内禀矫顽力温度系数 α(Hcj) |

典型值 |

最小值 |

典型值 |

最小值 |

Grade |

[T] |

[T] |

[kA/m] |

[kA/m] |

[kJ/m3] |

[℃] |

[℃] |

[%/℃] |

[%/℃] |

[KGs] |

[KGs] |

[KOe] |

[KOe] |

[MGOe] |

RE2Co17 175/199 |

0.99 |

0.96 |

700 |

1990 |

183 |

175 |

820 |

350 |

-0.03 |

-0.2 |

9.9 |

9.6 |

8.7 |

25 |

23 |

22 |

RE2Co17 175/143 |

0.99 |

0.96 |

700 |

1433 |

183 |

175 |

820 |

350 |

-0.03 |

-0.2 |

9.9 |

9.6 |

8.7 |

18 |

23 |

22 |

RE2Co17 191/199 |

1.04 |

1.02 |

750 |

1990 |

199 |

191 |

820 |

350 |

-0.03 |

-0.2 |

10.4 |

10.2 |

9.4 |

25 |

25 |

24 |

RE2Co17 191/143 |

1.04 |

1.02 |

750 |

1433 |

199 |

191 |

820 |

350 |

-0.03 |

-0.2 |

10.4 |

10.2 |

9.4 |

18 |

25 |

24 |

RE2Co17 191/80 |

1.04 |

1.02 |

750 |

796-1273 |

199 |

191 |

820 |

350 |

-0.03 |

-0.2 |

10.4 |

10.2 |

9.4 |

10-16 |

25 |

24 |

RE2Co17 207/199 |

1.07 |

1.04 |

756 |

1990 |

215 |

207 |

820 |

350 |

-0.03 |

-0.2 |

10.7 |

10.4 |

9.5 |

25 |

27 |

26 |

RE2Co17 207/143 |

1.07 |

1.04 |

756 |

1433 |

215 |

207 |

820 |

350 |

-0.03 |

-0.2 |

10.7 |

10.4 |

9.5 |

18 |

27 |

26 |

RE2Co17 207/80 |

1.07 |

1.04 |

756 |

796-1273 |

215 |

207 |

820 |

350 |

-0.03 |

-0.2 |

10.7 |

10.4 |

9.5 |

10-16 |

27 |

26 |

RE2Co17 207/44 |

1.07 |

1.04 |

413-716 |

438-796 |

215 |

207 |

820 |

350 |

-0.03 |

-0.2 |

10.7 |

10.4 |

5.2-9 |

5.5-10 |

27 |

26 |

RE2Co17 222/199 |

1.1 |

1.08 |

788 |

1990 |

239 |

222 |

820 |

350 |

-0.03 |

-0.2 |

11.0 |

10.8 |

9.9 |

25 |

30 |

28 |

RE2Co17 222/143 |

1.1 |

1.08 |

788 |

1433 |

239 |

222 |

820 |

350 |

-0.03 |

-0.2 |

11.0 |

10.8 |

9.9 |

18 |

30 |

28 |

RE2Co17 222/80 |

1.1 |

1.08 |

788 |

796-1273 |

239 |

222 |

820 |

350 |

-0.03 |

-0.2 |

11.0 |

10.8 |

9.9 |

10-16 |

30 |

28 |

RE2Co17 222/44 |

1.1 |

1.08 |

413-716 |

438-796 |

239 |

222 |

820 |

350 |

-0.03 |

-0.2 |

11.0 |

10.8 |

5.2-9 |

5.5-10 |

30 |

28 |

RE2Co17 239/143 |

1.12 |

1.1 |

772 |

1433 |

255 |

239 |

820 |

350 |

-0.03 |

-0.2 |

11.2 |

11.0 |

9.7 |

18 |

32 |

30 |

RE2Co17 239/80 |

1.12 |

1.1 |

772 |

796-1273 |

255 |

239 |

820 |

350 |

-0.03 |

-0.2 |

11.2 |

11.0 |

9.7 |

10-16 |

32 |

30 |

RE2Co17 239/44 |

1.12 |

1.1 |

413-716 |

438-796 |

255 |

239 |

820 |

350 |

-0.03 |

-0.2 |

Note: Curie temperature and temperature coefficient are for reference only, but not as inspection base.

|

|

|

|

|

|

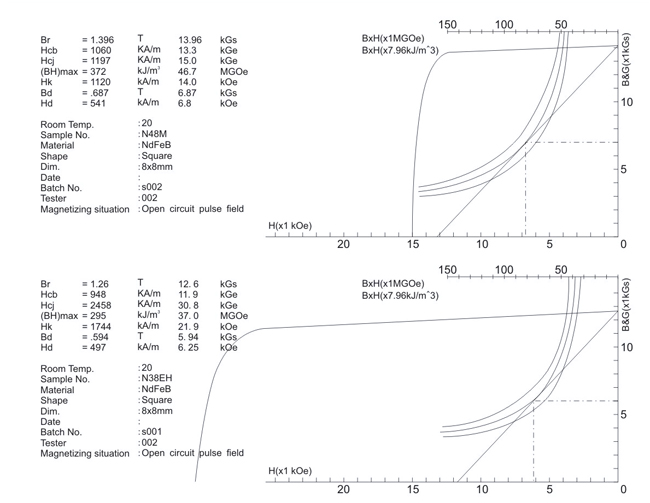

| Sintered NdFeB |

Features of Sintered NdFeB

The most powerful magnets commercially available

Manufactured by a powder metallurgical process involving the sintering of powder compacts under vacuum

Grinding and slicing possible

Very reactive with moisture and oxygen

A variety of Coatings can applied depending on the environment of the application

Applications:

Various types of electric motors, engineering equipment, medical equipment, audio apparatus and household

appliances

Magnetic property parameters of cast NdFeB

|

Br: KGs(mT) |

Hcb: KOe(KA/m) |

Hcj: Koe(KA/m) |

(BH)max: MGOe(KJ/m3) |

(Tw): °C |

N35 |

11.8-12.2(1180-1220) |

≥10800(860) |

≥12.0(955) |

33-36(262-286) |

80 |

N38 |

12.2-12.6(1220-1260) |

≥10800 (860) |

≥12.0(955) |

36-39(287-310) |

80 |

N40 |

12.6-12.9(1260-1290) |

≥10800 (860) |

≥12.0(955) |

38-40(302-318) |

80 |

N42 |

12.9-13.3(1290-1330) |

≥10800 (860) |

≥12.0(955) |

40-43(318-342) |

80 |

N45 |

13.2-13.7(1320-1370) |

≥10800 (860) |

≥12.0(955) |

43-46(342-366) |

80 |

N48 |

13.7-14.2(1370-1420) |

≥10500(835) |

≥11.0(876) |

46-49(366-390) |

80 |

N50 |

14.0-14.3(1400-1430) |

≥10500 (835) |

≥11(876) |

48-50(382-398) |

80 |

N35M |

11.7-12.1(1170-1210) |

≥10800 (860) |

≥14.0(1114) |

33-36(263-287) |

100 |

N38M |

12.2-12.6(1220-1260) |

≥10800 (860) |

≥14.0(1114) |

36-39(287-310) |

100 |

N40M |

12.5-12.8(1250-1280) |

≥10800(860) |

≥14.0(1114) |

38-41(318-342) |

100 |

N42M |

12.8-13.2(1280-1320) |

≥10800 (860) |

≥14.0(1114) |

40-43(318-342) |

100 |

N45M |

13.2-13.7(1320-1370) |

≥10800 (860) |

≥14.0(1114) |

43-46(342-366) |

100 |

N48M |

13.7-14.2(1370-1420) |

≥10.500(835) |

≥14.0(1114) |

46-49(366-390) |

100 |

N50M |

14.0-14.3(1400-1430) |

≥11500(915) |

≥14.0(1114) |

48-50(382-398) |

100 |

N35H |

11.7-12.1(1170-1210) |

≥10800(860) |

≥17.0(1353) |

33-36(263-287) |

120 |

N38H |

12.2-12.6(1220-1260) |

≥10800(860) |

≥17.0(1353) |

36-39(287-310) |

120 |

N40H |

12.5-12.8(1250-1280) |

≥10800(860) |

≥17.0(1353) |

38-41(318-342) |

120 |

N42H |

12.8-13.2(1280-1320) |

≥10800(860) |

≥17.0(1353) |

40-43(318-342) |

120 |

N45H |

13.2-13.7(1320-1370) |

≥10800(860) |

≥17.0(1353) |

43-46(342-366) |

120 |

N35SH |

11.7-12.1(1170-1210) |

≥10800(860) |

≥20.0(1592) |

33-36(263-287) |

150 |

N38SH |

12.2-12.6(1220-1260) |

≥10800(860) |

≥20.0(1592) |

36-39(287-310) |

150 |

N40SH |

12.5-12.8(1250-1280) |

≥10800(860) |

≥20.0(1592) |

38-41(318-342) |

150 |

N42SH |

12.8-13.2(1280-1320) |

≥10800(860) |

≥20.0(1592) |

40-43(318-342) |

150 |

N30UH |

10.8-11.2(1080-1120) |

≥10100(804) |

≥25.0(1990) |

28-31(223-246) |

180 |

N33UH |

11.3-11.7(1130-1170) |

≥10300(820) |

≥25.0(1990) |

31-33(247-263) |

180 |

N35UH |

11.7-12.1(1170-1210) |

≥10800(860) |

≥25.0(1990) |

33-36(263-287) |

180 |

N38UH |

12.2-12.6(1220-1260) |

≥10800(860) |

≥25.0(1990) |

36-39(287-310) |

180 |

N40UH |

12.6-12.9(1260-1290) |

≥11000(875) |

≥25.0(1990) |

38-40(302-318) |

180 |

N30EH |

10.8-11.2(1080-1120) |

≥10100(804) |

≥30.0(2388) |

28-31(223-246) |

200 |

N33EH |

11.3-11.7(1130-1170) |

≥10300(820) |

≥30.0(2388) |

31-33(247-263) |

200 |

N35EH |

11.7-12.1(1170-1210) |

≥10800(860) |

≥30.0(2388) |

33-36(263-287) |

200 |

N38EH |

12.2-12.6(1220-1260) |

≥11000(875) |

≥30.0(2388) |

36-38(286-302) |

200 |

N30AH |

10.8-11.2(1080-1120) |

≥10100(804) |

≥35.0(2785) |

28-31(223-246) |

220 |

N33AH |

11.3-11.7(1130-1170) |

≥10300(820) |

≥35.0(2785) |

31-33(247-263) |

220 |

N35AH |

11.7-12.1(1170-1210) |

≥10800(860) |

≥35.0(2785) |

31-35(247-279) |

220 |

|

|

|

|

|

|

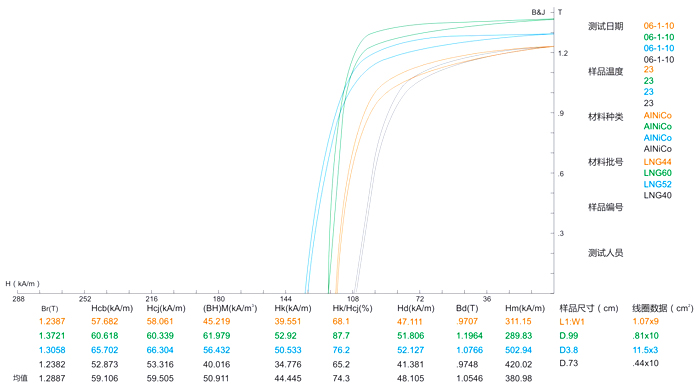

| Cast Alnico |

Features of Cast AlNiCo:

Vast range of complex shapes and sizes at an economical cost, ideal for high temperature applications up to 550℃

Good corrosion resistance density ranging from 6.9/cm3 to 7.39/cm3. A typical hardness of 50 Rockwell C, Machin-

able only by grinding;

Applications:

Automotive, Sensors and instruments, audio apparatus, electric motors, educational equipment and aerospace equipment.

Magnetic property parameters of cast Alnico

Magnetic property parameters of cast Alnico

材料牌号

Grade |

剩磁

Br |

矫顽力

Hcb |

最大磁能积

(BH)max |

剩磁温度

系数α(Br) |

矫顽力温度

系数α(Hcj) |

mT

Gs |

kA/m

Oe |

kJ/m3

MGOe |

%K |

%K |

LN10 |

600/6000 |

40/500 |

10.00/1.20 |

-0.02 |

0.03 |

LNG12 |

700/7000 |

44/550 |

12.00/1.50 |

-0.02 |

0.03 |

LNG13 |

680/6800 |

48/600 |

13.00/1.63 |

-0.02 |

0.03 |

LNG18 |

900/9000 |

48/600 |

18.00/2.25 |

-0.02 |

0.03 |

LNG37 |

1200/12000 |

48/600 |

37.00/4.63 |

-0.02 |

0.03 |

LNG40 |

1250/12500 |

48/600 |

40.00/5.00 |

-0.02 |

0.03 |

LNG44 |

1250/12500 |

52/650 |

44.00/5.50 |

-0.02 |

0.03 |

LNG52 |

1300/13000 |

56/700 |

52.00/6.50 |

-0.02 |

0.03 |

LNG56 |

1300/13000 |

58/720 |

56.00/7.00 |

-0.02 |

0.03 |

LNG60 |

1330/13300 |

60/750 |

60.00/7.50 |

-0.02 |

0.03 |

LNGT18 |

580/5800 |

90/1130 |

18.00/2.25 |

-0.02 |

0.03 |

LNGT30 |

1100/11000 |

56/700 |

30.00/3.75 |

-0.02 |

0.03 |

LNGT32 |

800/8000 |

100/1250 |

32.00/4.00 |

-0.02 |

0.03 |

LNGT38 |

800/8000 |

110/1380 |

38.00/4.75 |

-0.02 |

0.03 |

LNGT44 |

850/8500 |

120/1500 |

44.00/5.50 |

-0.02 |

0.03 |

LNGT48 |

900/9000 |

120/1500 |

48.00/6.00 |

-0.02 |

0.03 |

LNGT60 |

950/9500 |

110/1380 |

60.00/7.50 |

-0.02 |

0.03 |

LNGT72 |

1050/10500 |

112/1400 |

72.00/9.00 |

-0.02 |

0.03 |

LNGT88 |

1100/11000 |

115/1450 |

88.00/11.00 |

-0.02 |

0.03 |

LNGT36J |

700/7000 |

140/1750 |

36.00/4.50 |

-0.02 |

0.03 |

LNGT52J |

900/9000 |

140/1750 |

52.00/6.50 |

-0.02 |

0.03 |

Note: Curie temperature and temperature coefficient are for reference only, but not as inspection base. |

|

|

|

|

|

|

|

|

|