We are professional NdFeB, NdFeB magnet, SmCo magnet, AlNiCo magnet, Hard Ferrite magnet, rubber magnet, flexible magnet sheet, flexible magnet for micro motor, fridge magnet, magnetic toys, magnetic assemblies, bonded magnet manufacturer and factory in China. We can produce NdFeB magnet, sintered NdFeB magnet according to your requirements. More types of NdFeB magnets, sintered NdFeB magnet wanted, please contact us right now!

General Introduction

Sintered Magnet: is one of the high performance rare earth permanent magnets, which use neodymium (Nd), iron (Fe), and boron (B) as their main ingredients and is susceptible to demagnetization when exposed to elevated temperatures. There are many grades which can withstand high temperatures, but several factors will dictate the performance of the Neodymium magnet. There are Sintered NdFeB, Sintered AlNiCo, Sintered SmCo and Sintered Ferrite.

NdFeB magnets, have the characteristics of :

-

Super strong Br Resident induction.Excellent demagnetization resistance capability.

Good Price relative to its high magnetic properties.

Coating is needed for NdFeB

-

Surface Treatment Method: Type Information

Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+Copper+Nickel,

Gold, Organic Epoxy, Nickel+Epoxy coating

Temporary Surface: Passivation

Dimension Available

Sintered NdFeB Magnets production process >>

|

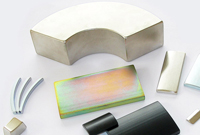

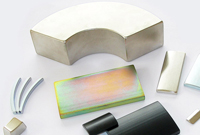

| What shapes can it be formed |

NdFeB magnet, Sintered NdFeB magnet |

|

|

| NdFeB magnets for motor, generator,driver in various specification |

Tile-shaped and special-shaped ndfeb magnet |

|

|

| NdFeB Blocks in various specification |

NdFeB products painted with epoxy resin |

|

|

| NdFeB Rings in various specification |

NdFeB Cylinders in various specification |

|

|

| Special Shape of NdFeB Magnet |

Rubber Coated NdFeB Magnet |

|

|

| Special Shape of NdFeB Magnet |

Magnetic Amazing Sphere |

Magnetic properties of Sintered NdFeB magnet: |

Grade |

Remanence |

Coercive Force |

Intrinsic Coercive Force |

Max. energy product |

Max.

Operating

Temperature |

Br

mT

(kGs) |

Hcb

kA/m

(kOe) |

Hcj

kA/m

(kOe) |

BH BH  max kJ/m3 max kJ/m3

(MGOe)

|

Tw |

N35 |

1170-1220

(11.7-12.2) |

868 868

(  10.9) 10.9)

|

955 955

(  12) 12)

|

263-287

(33-36) |

80  |

N38 |

1220-1250

(12.2-12.5) |

899 899

(  11.3) 11.3)

|

955 955

(  12) 12)

|

287-310

(36-39) |

80  |

N40 |

1250-1280

(12.5-12.8) |

907 907

(  11.4) 11.4)

|

955 955

(  12) 12)

|

302-326

(38-41) |

80  |

N42 |

1280-1320

(12.8-13.2) |

915 915

(  11.5) 11.5)

|

955 955

(  12) 12)

|

318-342

(40-43) |

80  |

N45 |

1320-1380

(13.2-13.8) |

923 923

(  11.6) 11.6)

|

955 955

(  12) 12)

|

342-366

(43-46) |

80  |

N48 |

1380-1420

(13.8-14.2) |

923 923

(  11.6) 11.6)

|

876 876

(  12) 12)

|

366-390

(46-49) |

80  |

N50 |

1400-1450

(14.0-14.5) |

796 796

(  10.0) 10.0)

|

876 876

(  11) 11)

|

382-406

(48-51) |

60  |

N52 |

1430-1480

(14.3-14.8) |

796 796

(  10.0) 10.0)

|

876 876

(  11) 11)

|

398-422

(50-53) |

60  |

30M |

1080-1130

(10.8-11.3) |

796 796

(  10.0) 10.0)

|

1114 1114

(  14) 14)

|

223-247

(28-31) |

100  |

33M |

1130-1170

(11.3-11.7) |

836 836

(  10.5) 10.5)

|

1114 1114

(  14) 14)

|

247-263

(31-33) |

100  |

35M |

1170-1220

(11.7-12.2) |

868 868

(  10.9) 10.9)

|

1114 1114

(  14) 14)

|

263-287

(33-36) |

100  |

38M |

1220-1250

(12.2-12.5) |

899 899

(  11.3) 11.3)

|

1114 1114

(  14) 14)

|

287-310

(36-39) |

100  |

40M |

1250-1280

(12.5-12.8) |

923 923

(  11.6) 11.6)

|

1114 1114

(  14) 14)

|

302-326

(38-41) |

100  |

42M |

1280-1320

(12.8-13.2) |

955 955

(  12.0) 12.0)

|

1114 1114

(  14) 14)

|

318-342

(40-43) |

100  |

45M |

1320-1380

(13.2-13.8) |

995 995

(  12.5) 12.5)

|

1114 1114

(  14) 14)

|

342-366

(43-46) |

100  |

48M |

1360-1430

(13.6-14.3) |

1027 1027

(  12.9) 12.9)

|

1114 1114

(  14) 14)

|

366-390

(46-49) |

100  |

50M |

1400-1450

(14.0-14.5) |

1033 1033

(  13.0) 13.0)

|

1114 1114

(  14) 14)

|

382-406

(48-51) |

100  |

30H |

1080-1130

(10.8-11.3) |

796 796

(  10.0) 10.0)

|

1353 1353

(  17) 17)

|

223-247

(28-31) |

120  |

33H |

1130-1170

(11.3-11.7) |

836 836

(  10.5) 10.5)

|

1353 1353

(  17) 17)

|

247-271

(31-34) |

120  |

35H |

1170-1220

(11.7-12.2) |

868 868

(  10.9) 10.9)

|

1353 1353

(  17) 17)

|

263-287

(33-36) |

120  |

38H |

1220-1250

(12.2-12.5) |

899 899

(  11.3) 11.3)

|

1353 1353

(  17) 17)

|

287-310

(36-39) |

120  |

40H |

1250-1280

(12.5-12.8) |

923 923

(  11.6) 11.6)

|

1353 1353

(  17) 17)

|

302-326

(38-41) |

120  |

42H |

1280-1320

(12.8-13.2) |

955 955

(  12.0) 12.0)

|

1353 1353

(  17) 17)

|

318-342

(40-43) |

120  |

45H |

1300-1360

(13-13.6) |

963 963

(  12.1) 12.1)

|

1353 1353

(  17) 17)

|

326-358

(43-46) |

120  |

48H |

1370-1430

(13.7-14.3) |

995 995

(  12.5) 12.5)

|

1353 1353

(  17) 17)

|

366-390

(46-49) |

120  |

30SH |

1080-1130

(10.8-11.3) |

804 804

(  10.1) 10.1)

|

1592 1592

(  20) 20)

|

223-247

(28-31) |

150  |

33SH |

1130-1170

(11.3-11.7) |

844 844

(  10.6) 10.6)

|

1592 1592

(  20) 20)

|

247-271

(31-34) |

150  |

35SH |

1170-1220

(11.7-12.2) |

876 876

(  11.0) 11.0)

|

1592 1592

(  20) 20)

|

263-287

(33-36) |

150  |

38SH |

1220-1250

(12.2-12.5) |

907 907

(  11.4) 11.4)

|

1592 1592

(  20) 20)

|

287-310

(36-39) |

150  |

40SH |

1240-1280

(12.5-12.8) |

939 939

(  11.8) 11.8)

|

1592 1592

(  20) 20)

|

302-326

(38-41) |

150  |

42SH |

1280-1320

(12.8-13.2) |

987 987

(  12.4) 12.4)

|

1592 1592

(  20) 20)

|

318-342

(40-43) |

150  |

| 45SH |

1320-1380

(13.2-13.8) |

1003 1003

(  12.6) 12.6)

|

1592 1592

(  20) 20)

|

342-366

(43-46) |

150  |

28UH |

1020-1080 (10.2-10.8) |

764 764

(  9.6) 9.6)

|

1990 1990

(  25) 25)

|

207-231

(26-29) |

180  |

30UH |

1080-1130 (10.8-11.3) |

812 812

(  10.2) 10.2)

|

1990 1990

(  25) 25)

|

223-247

(28-31) |

180  |

33UH |

1130-1170

(11.3-11.7) |

852 852

(  10.7) 10.7)

|

1990 1990

(  25) 25)

|

247-271

(31-34) |

180  |

35UH |

1180-1220

(11.8-12.2) |

860 860

(  10.8) 10.8)

|

1990 1990

(  25) 25)

|

263-287

(33-36) |

180  |

38UH |

1220-1250

(12.2-12.5) |

876 876

(  11.0) 11.0)

|

1990 1990

(  25) 25)

|

287-310

(36-39) |

180  |

40UH |

1240-1280

(12.5-12.8) |

899 899

(  11.3) 11.3)

|

1990 1990

(  25) 25)

|

302-326

(38-41) |

180  |

28EH |

1040-1090

(10.4-10.9) |

780 780

(  9.8) 9.8)

|

2388 2388

(  30) 30)

|

207-231

(26-29) |

200  |

30EH |

1080-1130 (10.8-11.3) |

812 812

(  10.2) 10.2)

|

2388 2388

(  30) 30)

|

223-247

(28-31) |

200  |

33EH |

1130-1170

(11.3-11.7) |

836 836

(  10.5) 10.5)

|

2388 2388

(  30) 30)

|

247-271

(31-34) |

200  |

35EH |

1170-1220

(11.7-12.2) |

876 876

(  11.0) 11.0)

|

2388 2388

(  30) 30)

|

263-287

(33-36) |

200  |

38EH |

1220-1250

(12.2-12.5) |

899 899

(  11.3) 11.3)

|

2388 2388

(  30) 30)

|

287-310

(36-39) |

200  |

30AH |

1080-1120

(10.8-11.2) |

812 812

(  10.2) 10.2)

|

2785 2785

(  35) 35)

|

223-255

(28-32) |

220  |

33AH |

1120-1170

(11.2-11.7) |

812 812

(  10.2) 10.2)

|

2785 2785

(  35) 35)

|

247-271

(31-34) |

220  |

|

Physical and Mechanical Properties of ndfeb: |

Thermal Conductivity |

7.7 kcal/m-h-�C |

Young�s Modulus |

1.7 x 104 kg/mm2 |

Bending Strength |

24 kg/mm2 |

Compressive Strength |

80 kg/mm2 |

Electrical Resistivity |

160 �-ohm-cm/cm2 |

Density |

7.4-7.55 g/cm3 |

Vickers Hardness |

500 - 600 |

|

|

Available coatings for sintered ndfeb magnet: |

Available Coatings: |

Surface |

Coating |

Thickness (Microns) |

Color |

Resistance |

Passivation |

|

1 |

Silver Grey |

Temporary Protection |

Nickel |

Ni+Ni |

10-20 |

Bright Silver |

Excellent against Humidity |

Ni+Cu+Ni |

Zinc |

Zn |

8-20 |

Bright Blue |

Good Against Salt Spray |

C-Zn |

Shinny Color |

Excellent Against Salt Spray |

Tin |

Ni+Cu+Sn |

15-20 |

Silver |

Superior Against Humidity |

Gold |

Ni+Cu+Au |

10-20 |

Gold |

Superior Against Humidity |

Copper |

Ni+Cu |

10-20 |

Gold |

Temporary Protection |

Epoxy |

Epoxy |

15-25 |

Black, Red, Grey |

Excellent Against Humidity

& Salt Spray |

Ni+Cu+Epoxy |

Zn+Epoxy |

Chemical |

Ni |

10-20 |

Silver Grey |

|

|

BH

BH